The past – fibres in the maritime croplands

Fibres since agriculture began. Craft-work to industrial process. Decline due to imports. A climate unsuitable for broad-acre fibre crops.

The hunters and first agriculturalists

Natural fibres tend to degrade, broken down by bacteria and fungi. Our knowledge of fibres therefore comes from very few remains, sometimes just the imprint of a plant on a piece of pottery. Similarly, seeds rarely last, unless their structure is preserved after being charred in fire or buried in a dry wall of a house. And even if seeds are found, as those of flax have been in excavations of sites dated to more than 5,500 years ago, it cannot be certain that flax was grown as a crop to make linen.

The National Museum of Scotland displays a fragment of rope made from crowberry Empetrum nigrum found at Skara Brae (between 3200-2400 BC), and pottery (3000-2400 BC) having an impression of twisted cord at Hedderwick in East Lothian and of woven cloth at Luce Sands near Wigton, and then ‘matted cattle hair fabric with twisted woollen and plaited horse hair cords’ (that’s three types of animal) from Sheshader on Lewis 1300-850 BC.

The oldest of these are around 5000 years ago. More examples are shown at the Museum from more recent periods, but consisting of mainly wool.

The historical record continues fragmented in this way. Excavations at Kebister (the Four thousand year old story of one Shetland township, see Sources) reveal a few seeds of flax, suggesting the agricultural use as fibre or oil crop; and also barley straw, but probably not as a rope or cord.

Imagination is needed, and reference to the plant parts found in other regions (see Man in the ice, in Sources) suggests what probably was harvested and used. The web site Woven Communities lists a wide range of plants including heathers, grasses, bramble and trees such as willow that have been used in recent centuries, and like simmens, a rope or cord made from oat stems, and used for tying down thatch, may well have been used before then (See Sources).

Further migration and settlement

From around 500 BC, iron age Celts, the Romans, and the later Norse, left little more evidence of their use of natural fibres than the people who lived here before them. Here are a few examples.

At the Roman fort and settlement of Carpow, occupied around 1900 years ago, at the influence of rivers Tay and the Earn in Perthshire, was found the best-preserved piece of lorica squamata or scale armour in Roman north-west Europe. This light armour was widely used in the Empire but few fragments remain. It consists of a linen (flax) backing on which are sown small scales of thin sheet bronze. There is no evidence as to whether the flax was grown here (see Feeding the Romans).

[to be completed]

Towards industrialisation

Several thousand years after the first migrants began to use natural products directly from the wild and then to grow and harvest them as crops, fibre plants began to be cultivated and processed on a small industrial scale.

Of the fibre plants grown in our region, the main ones have been flax (Linum usitatissimum) and hemp (Canabis sativa). Like most other of our crops, they were domesticated elsewhere and imported. It is difficult to establish whether nettle was ever grown here on an industrial scale but it was certainly used to make cloth.

Large-scale methods of growing flax and hemp were established in Britain well before the industrial revolution began around 1750. In England, plants introduced from the continent were recorded on monastic estates in Norfolk, at least since 1304 (Thirsk).

Industrialisation increased from the 1500s, mainly to reduce dependence on imports in times of inter-nation war and strife. In Henry VIII’s reign, hemp and flax were grown in England in a four course rotation that included also barley and wheat or rye. By the 1780s, large areas of flax were grown mainly in south west England, Lincolnshire and West Yorkshire.

Flax and other fibres in the croplands

In Scotland, flax growing for industrial processing and weaving into linen, using both home-grown and imported material, extends back to the 1500s. Areas cropped with flax increased in the early 1700s, for example in the Carse of Gowrie, between Dundee and Perth, and in various parts of south Angus.

Flax cultivation at a local scale occurred throughout the country. By the time of Andrew Wights journeys around Scotland, 1778-1784, flax was the basis of many small industries. On coming down from the north to Dunkeld, for example, he writes of the ‘beautiful haughs variegated with flax, corn and grass’; and of another location nearby, ‘Much flax is propagated. Flax is in great demand: every woman spins, and the yarn sells for ready money.’

Seventy years later, the Vegetable Products of Scotland (1850) by the seedsmen Peter Lawson & Son, gives an authoritative account of the state of fibre growing in the mid-1800s. They write that flax is the main plant fibre still grown, the best seed of which is imported from the Baltic. Their description of how the fibre is separated from the glutinous matter of the plant, both at craft and industrial scales, shows how seriously the plant was taken at that time, how improvements in the final product were the result of synergies between agricultural and industrial innovation and how these improvements led to returning plant matter to the soil as part-processed waste.

Hemp and nettle Of the other species, Lawson and Son report that hemp around 1850 is cultivable in some sheltered areas, but is too tender to be grown in a large commercial venture in Scotland. And they also list the stinging nettle Urtica dioica, but say that its cultivation for cloth making ‘has never been fairly attempted’. And then, ‘Like those of many other common plants, the superior merits of this generally accounted troublesome weed have hitherto been much overlooked’. Well put!

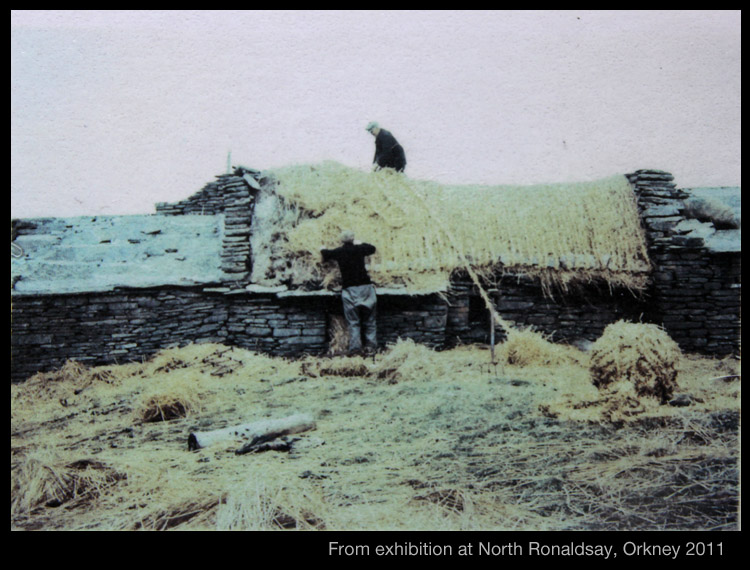

Simmens In some of the early photographs of rural life, people are seen plaiting plant material into ropes to secure thatch on houses or haystacks. These simmens were made of straw, mainly oat, heather or rushes. The oat straw would have been longer than in modern varieties of the plant. The black oat Avena strigosa grown in the living field garden can reach to 5 feet (1.5 metres) most of which is stem and leaf. But is was still a skilled craft to make rope that was tough enough for the job.

Quotations in the Scottish National Dictionary under ‘simmen’ (but note the many spelling variants) include: ‘These “simmons” are stretched in close parallel lines across the roof from eave to eave; and when the whole roof has been covered in this way, some loose straw is put over all, which is bound down by a second layer of “simmons” (Orkney 1874); and ‘Heather simmans are used mainly for thatched roofs. Straw simmans for corn stacks and byres. Sma’ simmans, made of crushed rushes of dog’s tail grass, for making creels, keyzes and cubbags’ (Caithness 1904).

To view some examples of rope, baskets and mats, search for ‘oat straw‘ in ‘materials’ at Shetland Museum and Archives on the RLS web site; more information at Sources.)

The image above shows men making simmens out of straw to be used to secure the thatch of a stone-built house in Orkney (date of original image unknown). Note the simmens stretched in tight parallel lines, as in the description above.

The end of arable fibre crops

So there were times when the tall flax plant was grown here on a field-scale as a fibre crop, and grown along with wheat, barley, turnip and oat and grass for grazing. It must have been familiar to rural people over thousands of years.

Despite the evident interest in flax at the time of the Lawsons’ account, home-grown material suffered competition from superior raw material imported from the Baltic region. And then throughout the 1800s, manufacture turned from homes to factories as the power loom became economical.

There was still money and prospects in factory-made linen, enough to finance the latest technology: in 1802, the Boulton and Watt steam engine, now restored at High Mill Verdant Works, was installed at Douglasfield works, Dundee, which bleached for the linen industry. But not long after this, local manufacture of linen all but disappeared.

Flax enjoyed a brief renaissance in the 1940s due to concern that imports would be cut during WW2. Around 9000 acres were grown and a processing plant set up in Blairgowrie. But the growing of flax for linen did not continue.

Flax is therefore one of the few major field crops once grown in recent centuries that is absent from the landscape today. Its end as a home-grown product made local textile industries entirely dependent on imported raw material.

Globalisation

Industries previously based on flax fibre led to major commercial ventures, but not with flax as the raw product. Jute and cotton took its place.

Jute The tall jute plants, grown in India and Bangladesh (see Fibre species of the world), are cut at the base, soaked in water or retted, stripped and washed, then the fibres are hung out to dry, bound in heavy bundles and shipped to the west.

Jute processing was a direct development of the linen industry in Scotland. The factories around Dundee already had the skilled workforce. Whale oil was available to soften the jute before processing. Supplies of flax became unreliable: the Baltic ports closed during the napoleonic Wars. The East India Company was looking for a market for its jute.

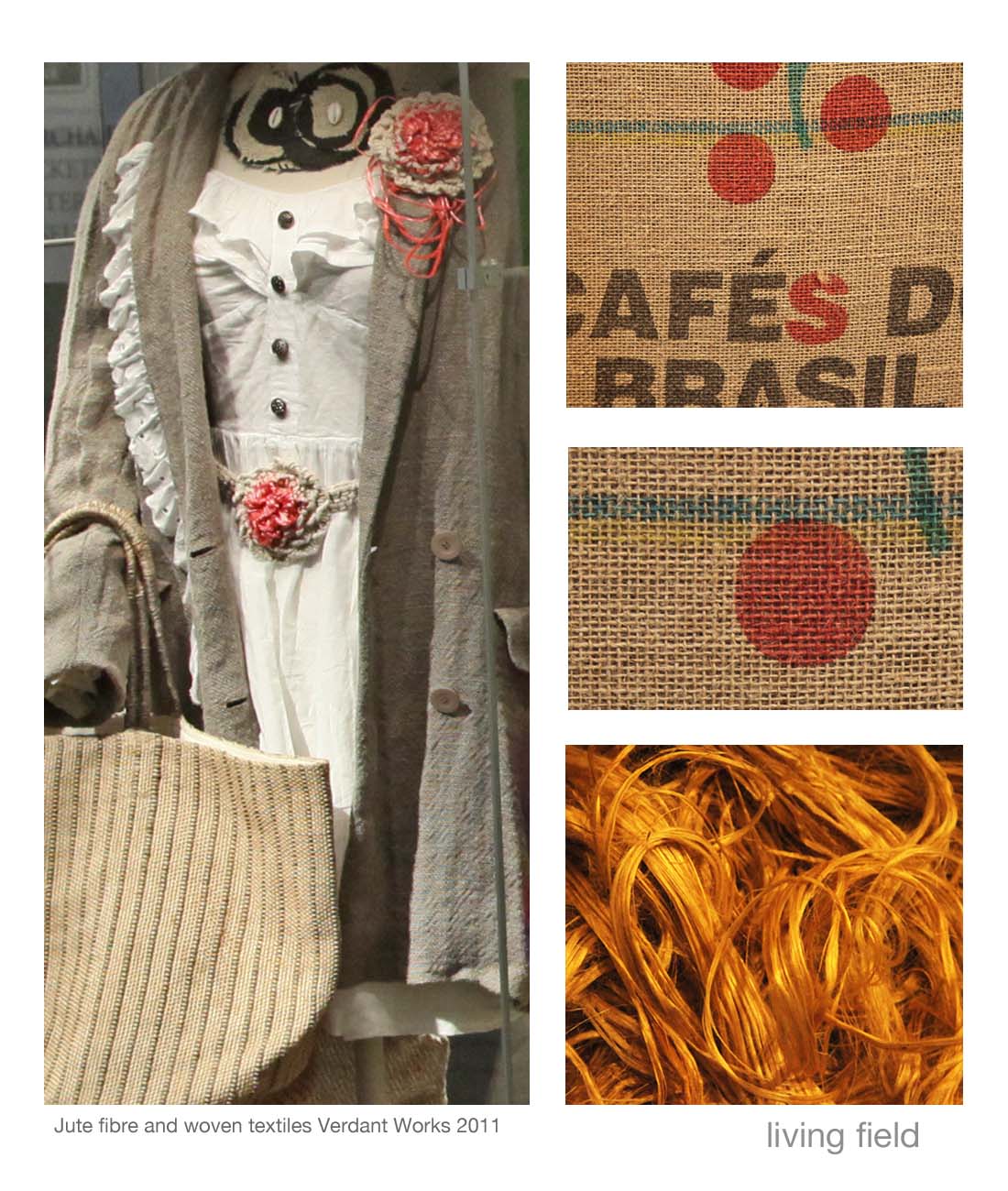

Too many pressures and jute won – and Dundee grew as a centre of manufacture, its populace trebling from 1841 to 1901 (information from Verdant Works). Jute made in Dundee went round the world: sacks for agricultural produce, car lining and upholstery, carpets, underfelt, roofing felt, rope and yarn, linoleum floor covering …. the list continues.

But jute manufacture in Dundee itself declined from the early 1900s as factories were built near where it was grown. Man-made polypropylene brought increased competition later in the 1900s. So jute continues to be an important fibre product, but grown and made elsewhere.

Cotton The economic potential of cotton can be gauged by the construction in 1786 of Stanley Mills in Perthshire – a set of factories, employing many people, built for the manufacture of cotton goods. The raw cotton fibre, imported mostly from north America, landed at ports in the west of Scotland, then came by road to the mills in Perthshire.

The fortunes of the mills were driven by external events. For example, the mills closed during the cotton famine of the 1860s – caused when cotton exports from the southern parts of what is now the USA ceased, because the northern forces blockaded the southern ports in the America Civil War. The resulting closure of the mills, here and in other places such as Lancashire, brought mass unemployment, and in some places starvation, especially where a large workforce had become both wage-dependent and divorced from agriculture.

Fortune returned for a time to the industry: by 1876, a major output of the Stanley Mills was cotton belting used in machinery throughout the world. By the mid-1900s, competing manufacturers in other countries brought the end of cotton production here.

Above: jute fibre from the Verdant Works Dundee, clothing made from jute and printed jute panel, both at the ‘Carriers to coffins’ exhibition held in 2011 (Living Field).

The present

Fibres as home-grown crops and imports. Their little contribution to the present ecology of the croplands.

Home-grown fibres

Though the maritime agriculture of the north-east Atlantic is diverse, no major crops are now grown for their extracted fibres. Only some small-scale craft industries still use local nettle and flax.

The main use of locally grown plant fibrous material is in the wood-based fibreboard industries, the raw material for which is produced in the plantation forest of the uplands or else overseas, in the use of thatch as roofing on a small scale and cereal straw as insulation and building material.

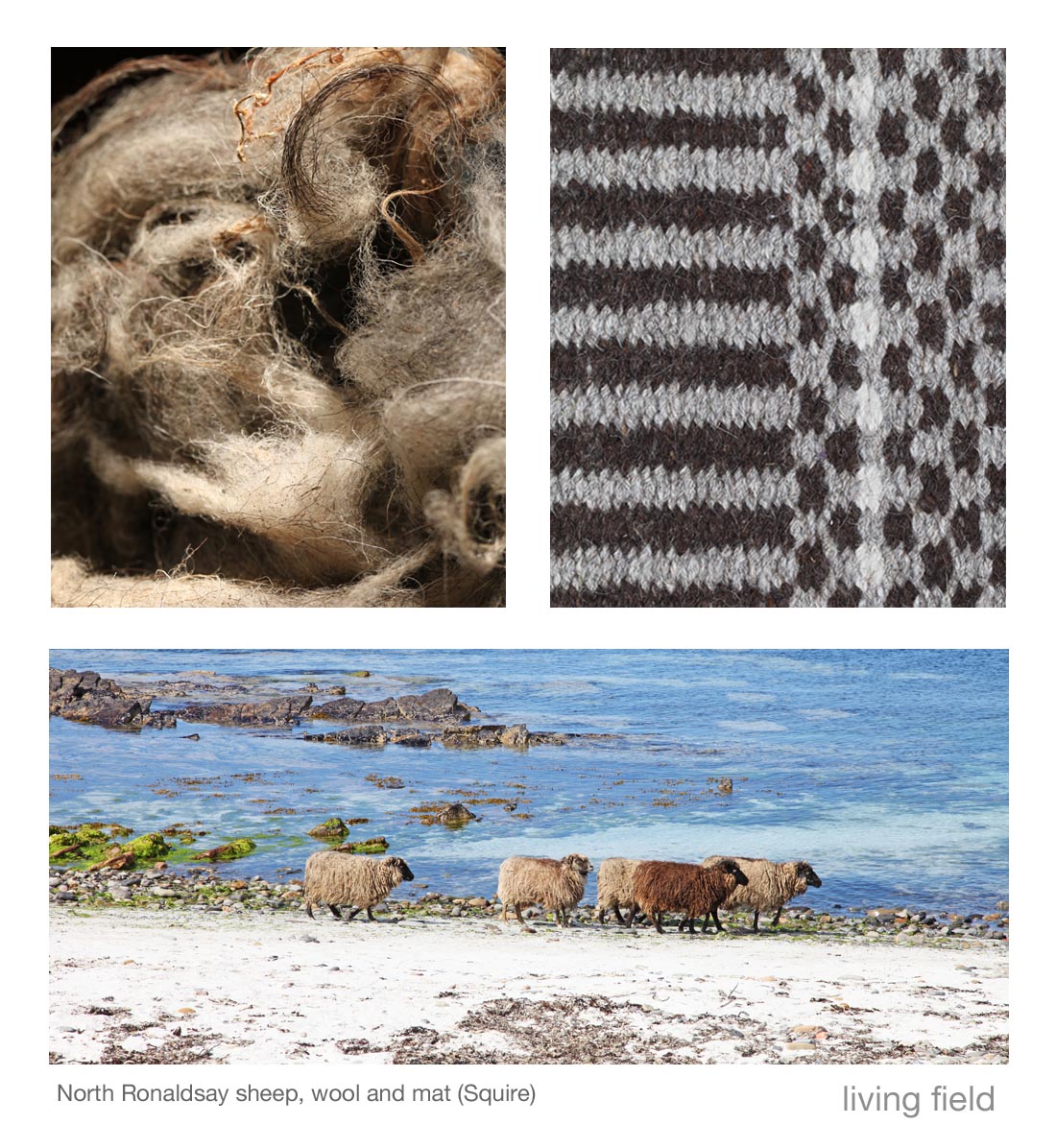

The main other source of natural fibre still harvested and processed is wool from sheep, but the profit to sheep farming of selling fleece dropped in the 1980s and remains low. Nevertheless, the use of sheep’s wool goes back well before agriculture and is still the base of major knitwear and textile industries in Scotland. Some breeds or landraces of sheep give distinctive wool yarn that can be woven into carpets, rugs and clothing material for niche markets (see Sources and images from North Ronaldsay below).

Various attempts have been made from the 1980s to increase the growing of flax and hemp. Some, such as hemp for paper making, were successful on a small scale. The largest visible change to the countryside, the more so in England, came not from a fibre crop, but from the blue-flowering, oilseed varieties of flax known as linseed. But they too have receded.

Imported fibres

In contrast, imported plant fibres – sometimes in a raw state – are still wildly used in a range of traditional and innovative industries. Among these are jute from India or Bangladesh, made into string, rope, sacking, lino, underlay and canvas. Jute is making a comeback as a multi-purpose, biodegradable alternative to polypropylene, which being made from the oil industries, is finite in supply and not biodegradable. (See ‘prospects’ below for recent uses of jute.)

Linen from Baltic flax is made into clothing and cloth. Even craft-scale manufacturers that use nettle fibre tend to rely on imports of the nettle family that produce longer fibres.

However, the plant fibres that we use, touch, smell and see are imported as finished or nearly finished products whose base is variously cotton, silk, hemp, flax and jute. If Scotland was suddenly forced to clothe itself from local products, it would have to rely on wool and hide. It would have difficulty growing the required plant fibres, just as it would the required plant carbohydrates for food.

Contribution to the ecology

Fibre plants that have been cultivated or harvested from the wild in our region for >8000 years now make only a small contribution to the flora and food webs. This contrasts with some of the cultivated brassica family, for example, that are still common as crops but also as weeds and ferals.

Nettle of course is everywhere, not because it was grown as a broad-scale fibre crop, but because it is naturally widespread, long lasting and opportunistic. However, its presence around most derelict crofts and farm buildings may be local relic from previous usage both as food, dye and fibre, as well as a weed taking advantage of urine-enriched soil.

Flax, or linseed, the oilseed form of the species, is still found occasionally as relic of cultivation, but more commonly as a part of sown habitat for game and wild birds in strips and corners of fields, where its pale blue flowers sometimes mingle with the yellow and white of sown radish and mustard. Hemp occurs as a relic but less so in the north than flax.

The plants that were once harvested and processed for their fibres or fibrous structures and still remain are not the crops but the wild grasses, brambles, heathers and willows that (mostly) have been here since the retreat of the ice.

Prospects

New uses for home-grown and imported plant fibres. The likely continued absence of fibre crops from the landscape.

Prospects for plant fibres seem mainly in the processing and manufacturing rather than the growing industries. As the 2011 exhibition of jute products in the Verdant Works, Dundee, shows, there are new uses of imported jute to make bags and clothing, covers for chairs and sofas, geotextiles for stabilising slopes and, as compressed fibre pulp, biodegradable coffins for people and their pets. It looks like jute imported from India and Bangladesh will continue to a line of tradition in local industry, albeit in much reduced volumes.

And as indicated under Present, the largest volumes of fibrous materials available for development into possible new uses are from sheep, cereal straw and trees. The use of wool and cereal straw as home insulation and tree pulp in various fibreboard manufactures are examples. Houses made from cereal straw bales are being sold on the commercial market. The fabric, rayon, made from wood fibres may find new uses.

Specialist cloth and rugs will continue to be iconic products – Harris tweed, and products from rare sheep breeds such as the North Ronaldsay, the Jacobs and the Herdwick from Cumbria.

Conclusion

The ancient fibre crops, flax and hemp, have been in competition with cereals at various times in the last 1000 years and have usually lost, and seem to be still losing, especially if cereal straw expands as a building material.

The landscape may continue to be devoid of main fibre crops for the forseeable future. Nettle will remain in many habitats but, as the Lawsons noted in 1850, viewed mainly as a troublesome weed, its potential unrealised.