By Jean Duncan

Oak galls are small spherical growths that form on oak trees where the gall wasp lays its eggs in the buds of the tree. The tree grows tissue around the egg which protects the wasp until it hatches, leaving a hole. Watch out for a hole in the gall before harvesting.

The end of the summer is a good time to harvest, I find the galls are easier to spot once the leaves have fallen. If you can’t find them, you can buy oak gall powder/whole oak galls online [1].

Drawing Ink

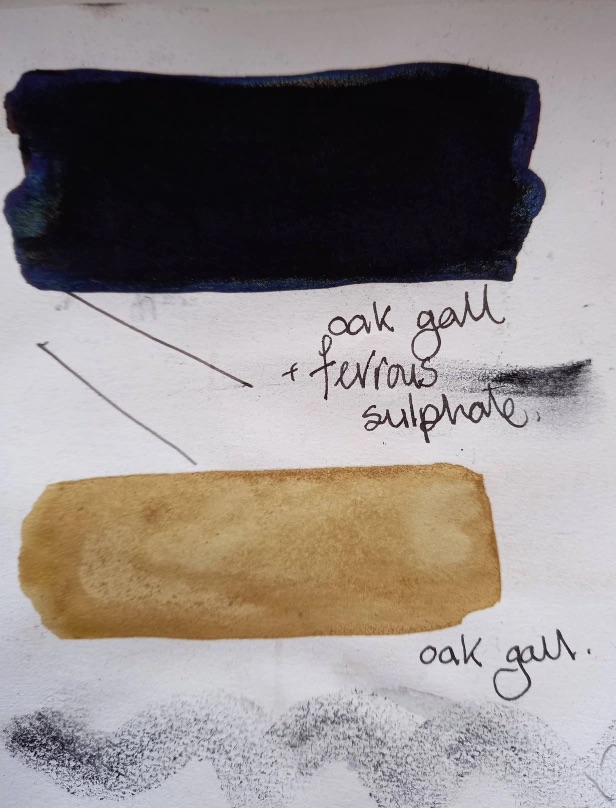

With the addition of iron, oak galls make a permanent ink. The method involves a reaction between tannic acid extracted from the galls and ferrous sulphate. The ink would once have been used with a quill and later a dipping pen.

Oak gall ink can still be seen on early manuscripts, though many are damaged due to the acidity of the tannic acid, which eats away at the natural fibres of paper, parchment or vellum [2]. To avoid such damage, recipes now use less ferrous sulphate.

Recipe This makes 250 ml of ink.

To make a permanent oak gall ink you will need ;

- 30 g of whole oak galls or oak gall powder.

- Pestle and mortar

- Scales

- Rain water

- Muslin

- 15 g ferrous sulphate powder *

- 7 g gum arabic solution

- Glass jar for storage.

*Can be purchased as blue green crystals or white powder.

Method

- Crush the oak galls with a pestle and mortar or put them in a bag and mash them with a hammer.

- Add 30 g oak gall powder to 25 ml of water and leave to soak for 24 hrs.

- Strain the liquid through the muslin.

- Mix the ferrous sulphate into the strained solution.

- Add the gum arabic and stir well

- Add oil of cloves or any other essential oil to help it keep for longer and store in the fridge.

- Try using the ink with a pen and a brush to see that it flows well, if the ink has a dusty surface add more gum arabic.

It is worth experimenting with washes of ink, as it turns blacker when it reacts with oxygen from the air.

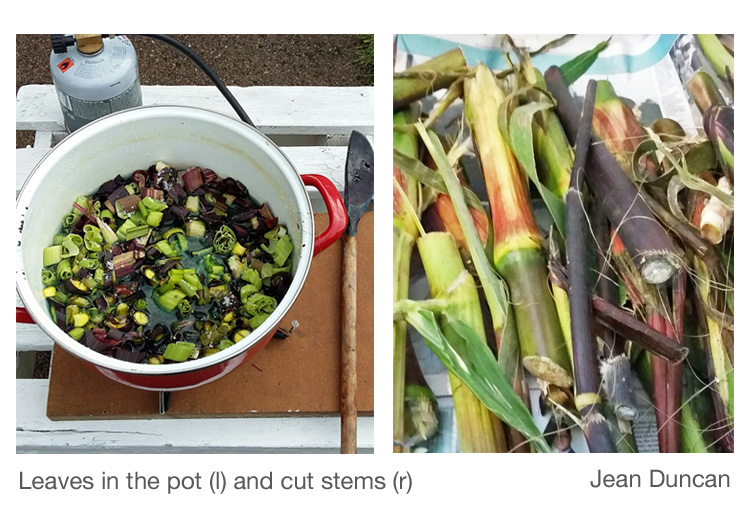

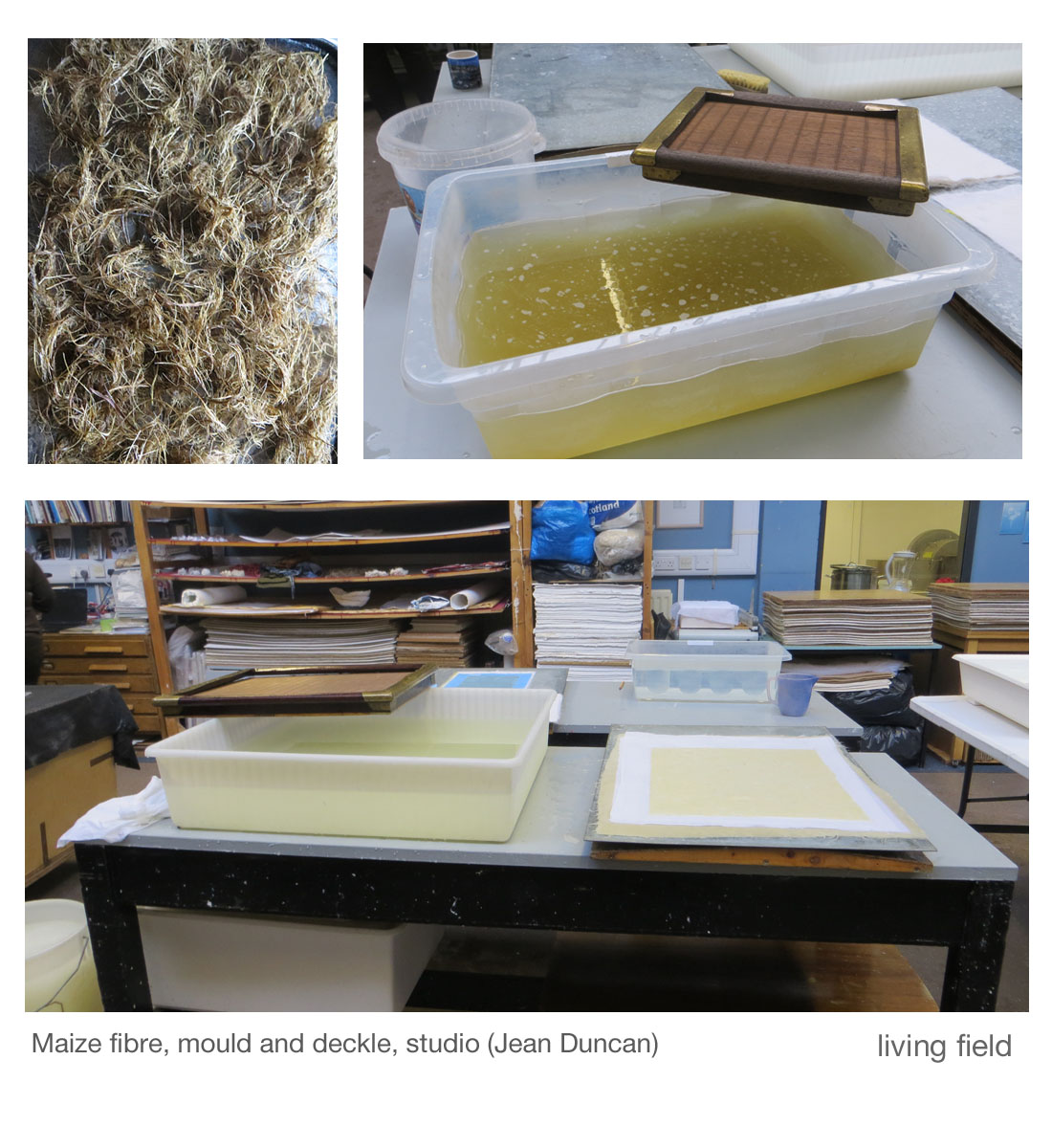

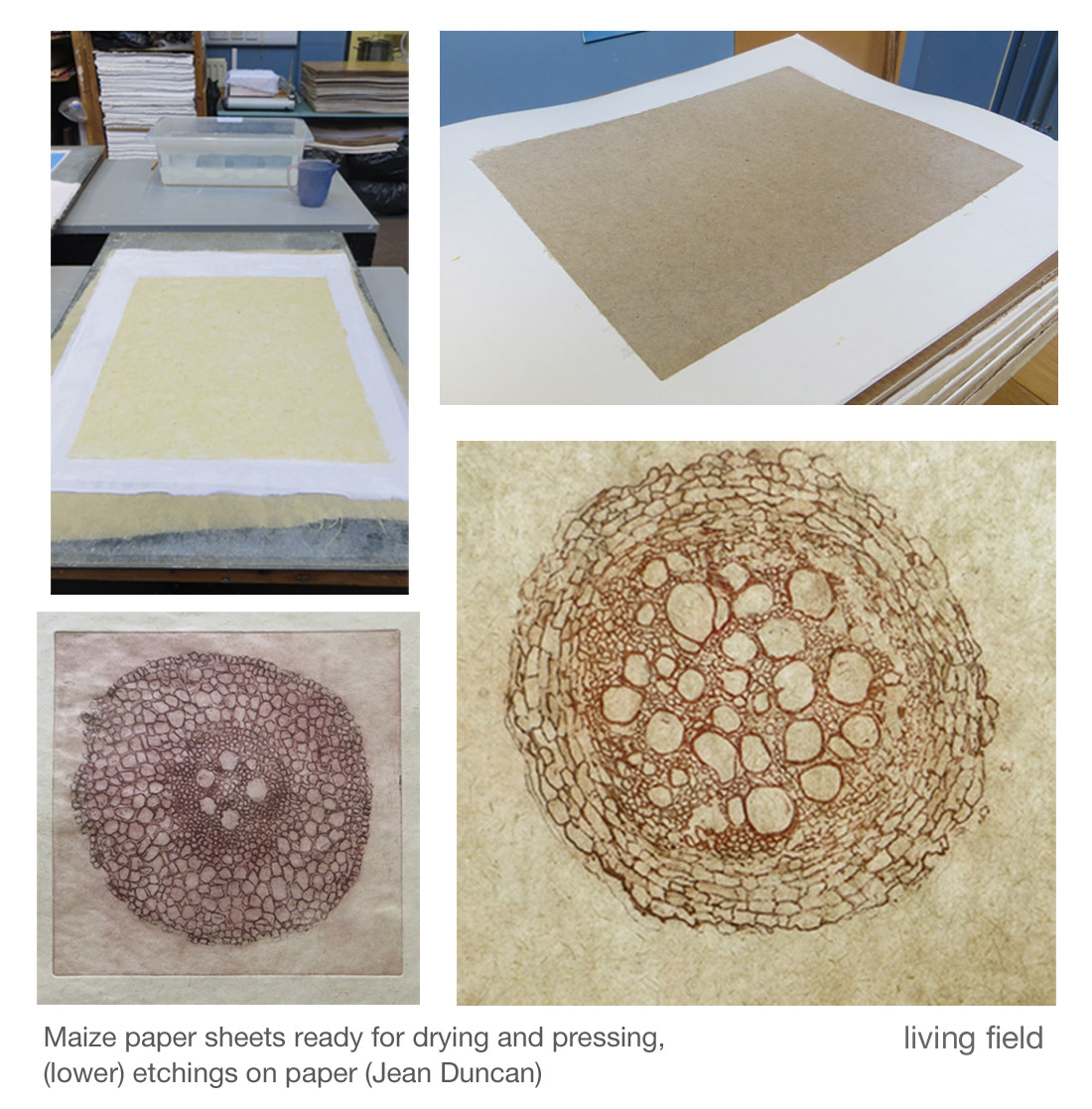

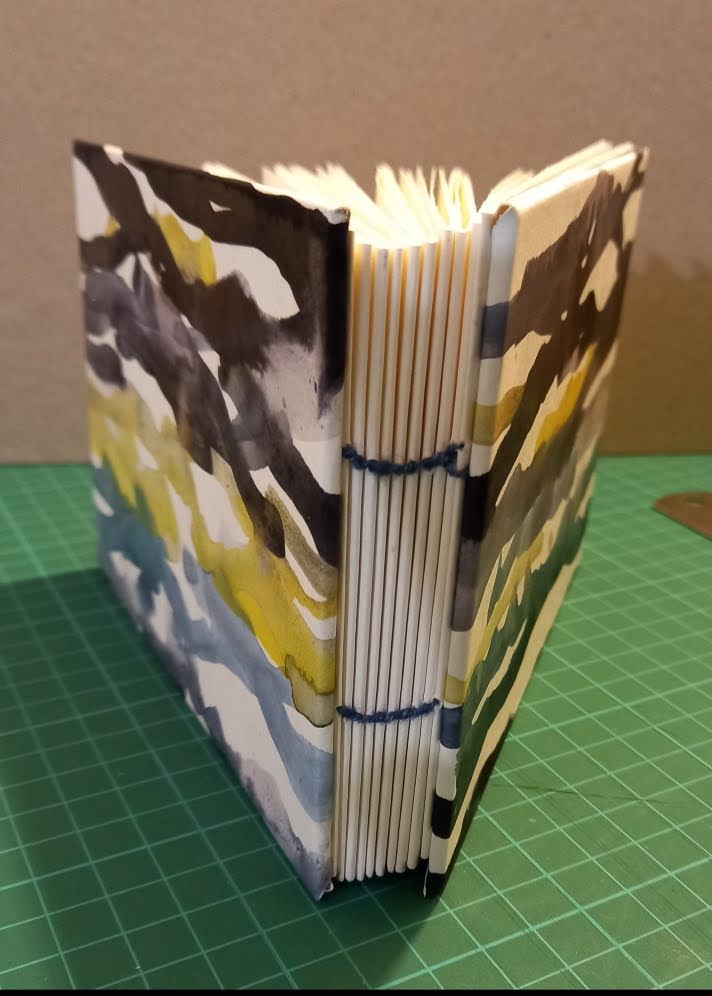

I wanted to make my own inks and watercolours to help create a sense of place in my drawings through botanical colours from my local environment, while consciously moving away from synthetic printing colours which are often unpleasant to use, toxic and harmful to people and the environment.

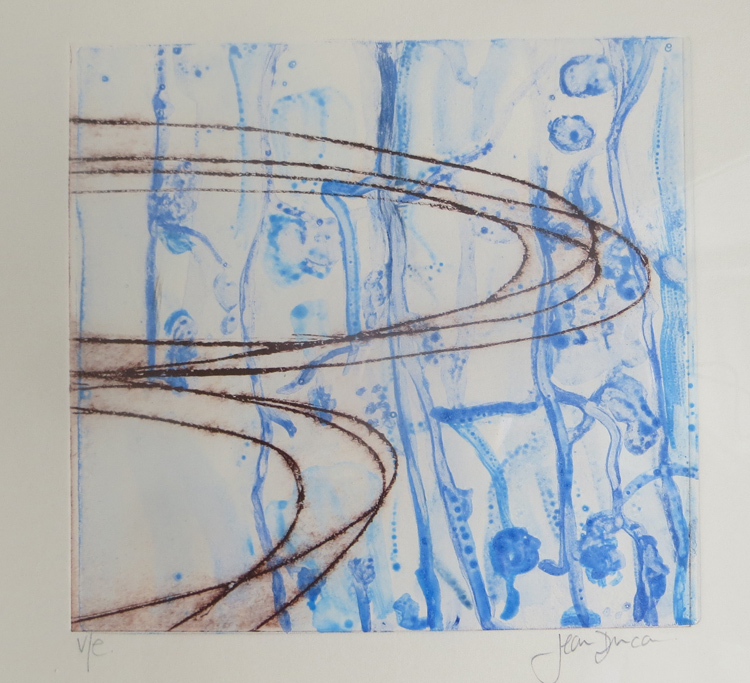

The photograph above shows a blend of colours produced on paper by oak gall ink and barley ink, the latter from orzo, a caffeine-free drink made from barley.

There are many artists and artisans working in this way and small businesses are leading the way in using locally sourced materials and natural dyes to make cloth that at the end of it’s life can be put back into the earth as a biological nutrient rather than a pollutant. I have given links below to two Fibreshed businesses working in this way [3, 4] and to an article on making ink from up-cycled coffee grounds [5].

Sources | Links

[1] To buy oak gall ink: George Weil fine art and craft supplies.

[2] Sakura Tohma (2015) Making and testing Iron Gall ink. West Dean College web site.

[3] Bristol Cloth – wool and botanical inks: South West England Fibreshed.

[4] More Fibreshed – Wool from the border between the Yorkshire Dales and Cumbria, : Laura’s Loom.

[5] European Horizon magazine: Eco espressso and upcycled inks set to make coffee greener. Some interesting facts in this article: black printing ink is more expensive than Chanel No 5, and the daily ‘waste’ in coffee grounds is equal to the weight of three Eiffel Towers!

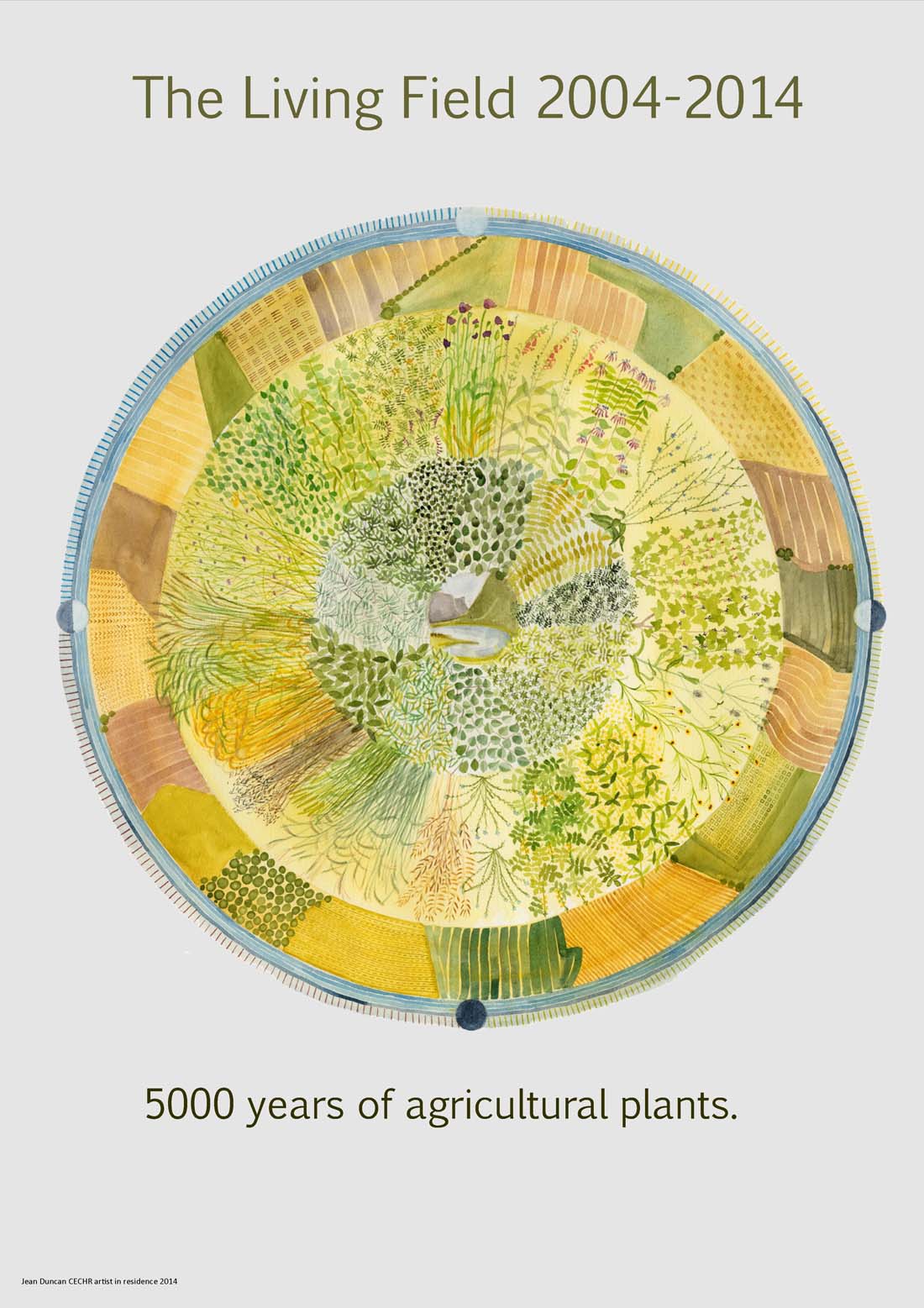

Jean Duncan is based in Fife. See her web site at JeanDuncanArtist. Jean has worked with the Living Field on many projects, exhibitions and events – her work is profiled at this Living Field page.

The photographs below are of an oak gall and oak leaf from the Living Field collection