David Brown is a farrier, based in Perthshire, with decades of experience in shoeing horses and fabricating metal.

In recent years, he’s been delighting family and friends with craftwork, whether wood-fires, garden ornaments or house-signs, all made from a collection of rods, plates and cylinders.

Examples of his work can be seen online [1] . The photograph below shows some of the parts being combined to make a house-sign .

Earlier in February, the Living Field went to find out how David works the metal into lettering and complex shapes of plants and animals.

It’s all done at a workshop within an old stone outbuilding in the Braes of the Carse between Dundee and Perth.

Firing scrap

The first thing noted was that the raw materials are mostly from unwanted or scrap metal. Take the rods, tied in bundles in the photograph above. They became unfit for their original purpose in the construction industry and would have been thrown away. Yet they are ideal for making things like ornamented pokers and lettering.

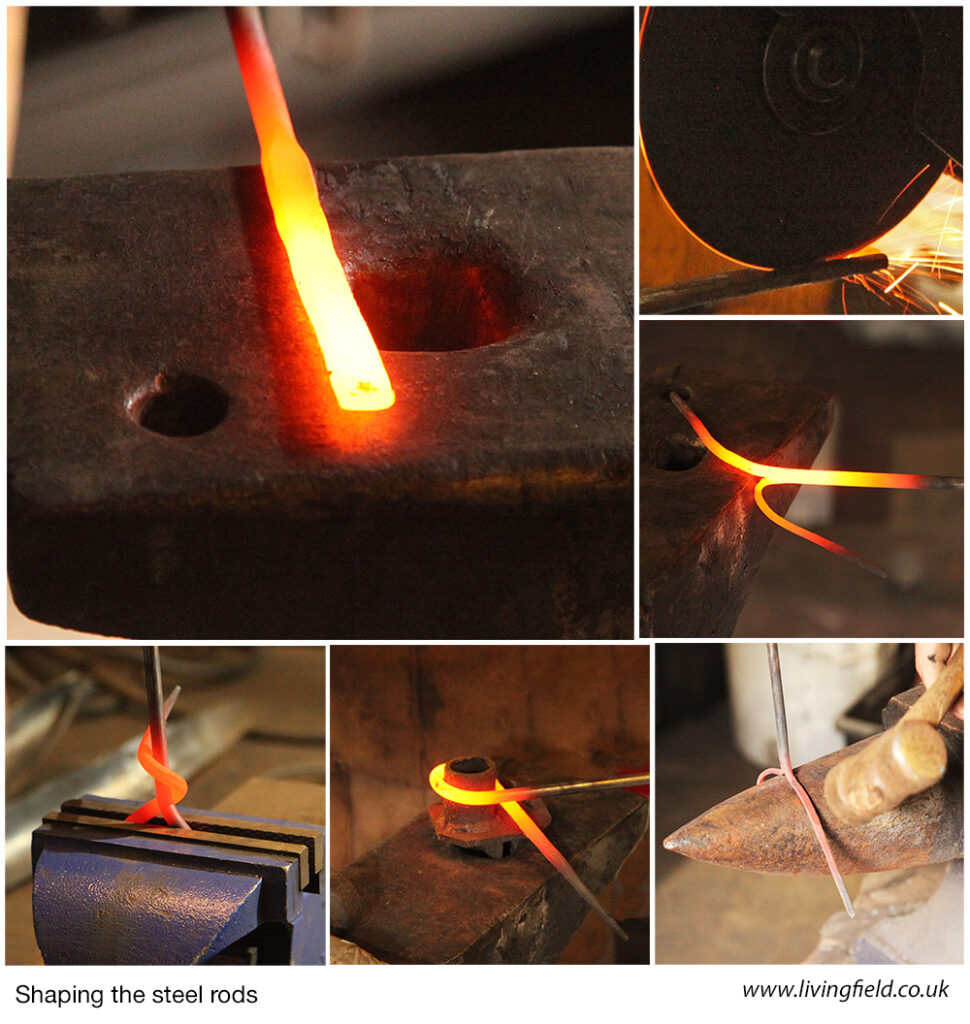

To become malleable, the rods are first fired in the forge until white hot, then the hot end is placed on the anvil ready for the hammer.

Hammering, sawing, bending, twisting

A range of techniques can used to create shapes out of the fired rods. First, the rods are usually beaten with a hammer to ‘flatten’ the last few inches of the rod into an oblong.

When cool, the flattened ends can be cut with a circular saw to form two prongs, like a tuning fork. The rod then goes back in the forge until it’s white hot again and in this form, the two prongs can be bent or hammered into shape.

Or the white hot rod can be left as a cylinder, but twisted round a ‘plug’ inserted into the anvil or held in a vice and curled into a spiral.

Power of the plasma cutter

Shapes are usually made from discarded steel or iron plate. An outline is drawn on the metal, then a hand-held plasma cutter traces the shape to release it from the plate. A powerful thing, this plasma cutter ….. and it makes a cascade of sparks!

The shape can then be re-heated and bent, cut or hammered to add spirals and other patterns.

From discard to craftwork

It was heartening to see David’s positive efforts to turn waste metal into things useful and ornamental. Here’s two examples.

In the panel above, discarded metal discs (top right) were first cut radially into several segments, some taken out to near the centre, those remaining moulded into the form of leaves or petals, given texture by repeated blows from a special hammer. When aligned on a central rod, the discs combine into whorls of leaves or flowers.

In the lower photographs, metal was taken from an old calor gas cylinder, flattened and cut into the form of a hare.

The workshop is a place of fire, sparks, hammering and hot metal – amazing to see it all. And there is little duplication: each piece is hand made and unique.

Links

[1] Knapp Forge and Flora – a page on facebook.

Ed: the Living Field thanks David for the invitation to his workshop and forge and for demonstrating some of his metalworking techniques.